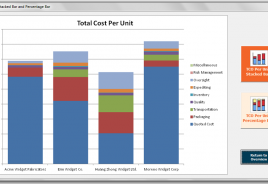

Total Cost of Ownership

Total Cost of Ownership (“TCO”) is a concept that examines all of the costs related to the acquisition, transportation, and storage of products within the supply chain. It goes way beyond the traditional view of piece price which can miss up to 40 percent of the actual cost of a raw material. While piece price is important, and will most likely account for the largest portion of TCO, there are many other categories to consider.

Let’s take a look at a few of the additional costs that are included in TCO.

Shipping Costs

Shipping costs and complexity tend to increase with distance. When borders intervene and ocean (or air) transport becomes involved, the complexity goes up significantly because of multi-modal shipping with potential transfer, inspection, storage and documentation requirements associated with each mode involved. A company importing goods must comply with a range of U.S. government requirements as well as the export regulations of the country of origin. Upon arrival in the United States, arrangements must be made to file entry documents at the port of entry, pay the estimated import duties, and secure the release of the goods from U.S. Customs and Border Protection. Companies often employ agents or brokers to assist them with these tasks. Each step in this chain of events involves costs that are often missed when determining the true cost of a product.

Shipping Time

Travel time for a container vessel from Asia to the U.S. is between two and four weeks. Documentation, customs clearance, handling, and inland shipping can add 18 to 32 days to the total shipping time from most emerging market regions, and another 6 days once goods reach the United States. The impact that shipping time has on cost involves the need to carry sufficient buffer inventory to cover customer demands until replenishment inventory arrives.

Inventory

The cost of buffer inventory is often absent from the traditional determination of cost. Costs involve not only the dollar value of the inventory itself, but also the financing cost of the investment and carrying costs related to storing excess inventory.

Quality Costs

Unforeseen or uncontrolled quality problems from a supplier may lead to:

- Lower product quality – increased inspection, unhappy customers

- Potentially costly product returns and shortages

- Possible legal liability

- Inability of supplier to meet certification, safety or other regulatory issuesEfforts to anticipate, control, mitigate or resolve the above quality issues will result in increased travel and oversight time and cost for this supplier.

Travel Costs for Supplier Oversight

Executives and other employees may need to travel to further develop or strengthen relationships; to oversee design, production, or shipping; or to resolve unforeseen issues like supply chain disruptions or production errors. Travel, labor and other related costs need to be included in the total cost of ownership.

Managing an efficient, optimized supply chain requires us to understand the total cost of ownership and how it impacts the strategic sourcing process. It also helps to determine what improvements can be made with existing key suppliers to reduce your current total cost of ownership.

I have a spreadsheet with over 80 inputs, broken down into 11 categories, capable of collecting and calculating your true TCO of any sourced item. I would be happy to work with you to populate this spreadsheet with your data. Contact me to get started.